Home < News < Elastomeric Bearing Pads: The Complete Professional Guide for Bridge Designers and Contractors

Far from being a simple slab of rubber, an elastomeric bridge bearing is the critical, precision-engineered "structural joint" of any bridge. It performs a silent yet vital multi-tasking role: supporting immense weight, accommodating thermal expansion and contraction, allowing for rotational movement, and mitigating seismic forces. For bridge designers and builders, selecting and installing the correct elastomeric bearing pad is a foundational decision that directly impacts the safety, longevity, and economic performance of the entire structure. This guide provides a comprehensive, professional breakdown of design theory, selection logic, and installation mastery.

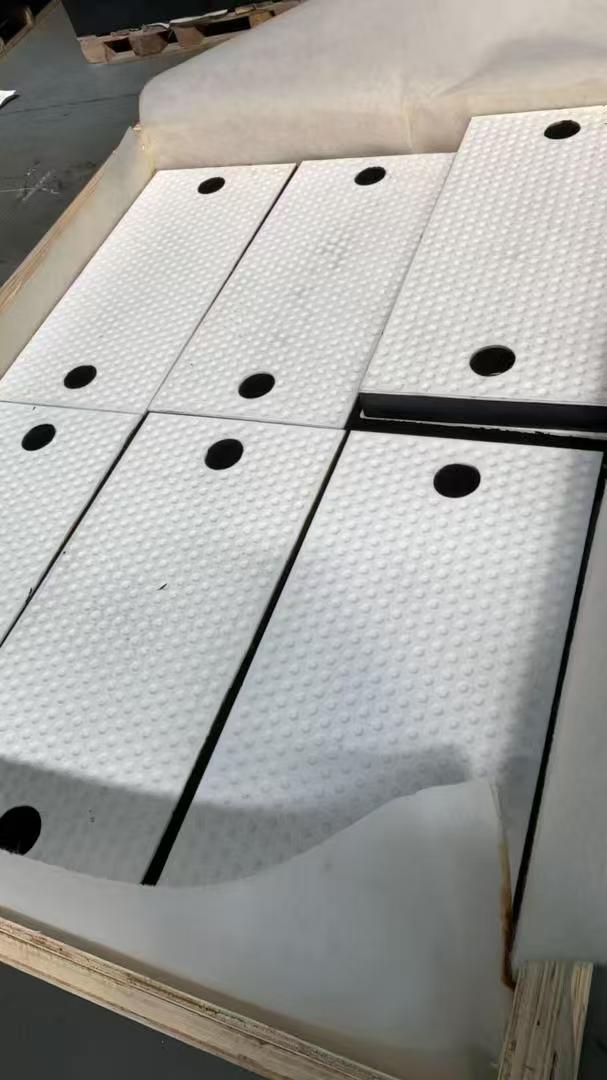

At its core, the genius of a laminated elastomeric bearing lies in its composite construction. Layers of high-quality elastomer (like neoprene or natural rubber) provide flexibility, while bonded steel reinforcement plates constrain the rubber, creating a component that is vertically stiff yet horizontally flexible.

The behavior of a bearing is governed by two dimensionless shape factors:

Primary Shape Factor (S1): This measures the confinement of a single rubber layer. A higher S1 indicates greater confinement, leading to higher vertical stiffness and compressive strength. It is crucial for preventing bearing instability under load.

Secondary Shape Factor (S2): This relates the total bearing thickness to its plan dimensions. It primarily influences the bearing's stability against buckling and its ability to accommodate rotational movements (beam end rotations).

Professional design requires precise calculation of these key properties:

Compressive Stiffness (Kv): Not a constant value, Kv depends on S1 and the rubber's hardness. Accurate calculation is essential for predicting beam deflections and load distribution.

Shear Stiffness (Kh): Governed by the rubber's shear modulus (G) and effective area, this determines the force required to displace the bearing horizontally. It is fundamental for designing for thermal movement and seismic resistance.

Rotation Capacity: The bearing allows rotation through internal, non-uniform compression of the rubber layers. Design must verify that the bearing edge does not experience excessive lift-off (loss of contact) under maximum design rotation.

·

Choosing the right bridge bearing is a systems-engineering decision based on a full lifecycle analysis.

A thorough analysis is the cornerstone of correct selection:

Vertical Loads: Permanent (dead) and variable (live, traffic) loads.

Horizontal Movements: Calculated from the bridge's total length, material, and the local extreme temperature range. For curved bridges, include effects of centrifugal force and prestressing.

Rotational Demands: Based on anticipated beam end rotations under various load cases.

Seismic Requirements: Displacement and energy dissipation needs based on seismic zone.

·

2.2 Step 2: Bearing Type Selection Matrix

2.3 Step 3: Writing a Fail-Safe Specification

Move beyond just dimensions. A professional specification must mandate:

Performance Parameters: Design pressure, max shear strain (e.g., ≤250%), allowable rotation, and shear modulus (G) value with tolerance.

Material Standards: Specify elastomer type (e.g., Chloroprene/Neoprene for ozone resistance), steel grade, and adhesive standards.

Testing Protocol: Require prototype test reports showing compressive stiffness curves, shear hysteresis loops, and aged property data from an accredited lab.Part 3: Installation Excellence: The Contractor's Field Manual

For contractors, the installation process is where design performance is made real. A perfectly specified bearing can fail if installed incorrectly.

"Receipt Inspection" Checklist:

Documentation: Verify mill certificates for rubber/steel, independent test reports, and manufacturer's certification.

Visual Inspection: Check for surface defects, cracks >2mm deep, or incomplete vulcanization. Ensure steel plates are free of corrosion.

Dimensional Check: Use calipers to verify overall height and layer thickness against tolerances (e.g., height tolerance of ±0.5%).

o

Treat bearing installation as a precision alignment operation.

Preparation of Support Surface (Masonry Plate/Concrete Pedestal):

This is the most critical step. The surface must be level, clean, and at the exact design elevation.Flatness Tolerance: Typically ≤1/500 with no localized high spots. Grind high points and use non-shrink, high-strength epoxy grout to correct low areas—never use steel shims or standard mortar.

3.Precise Placement and Leveling:

Use soft slings for lifting to avoid damage.

Align bearing centerlines with reference marks on the support.

Use a precision machinist's level or digital inclinometer. Final levelness should be within 0.2% of bearing width. Micro-adjustment with approved stainless steel shims is permissible if properly secured.

Grouting and Securing (for anchored types):

Use a flowable, non-shrink structural grout. Pour from one side until it flows out the other, ensuring the cavity is completely filled without air pockets.

Do not disturb the bearing or proceed with superstructure construction until the grout has achieved its specified strength.

Final Verification Checklist:

Centerline deviation ≤ 2mm.

Top surface level within specification.

No visible gaps between bearing base and support (check with feeler gauge).

All protective films/coatings on sliding surfaces removed.

Photographic documentation taken, noting ambient temperature.

Common Field Issues & Professional Response:

Problem: After girder placement, bearing shows visible uneven compression (bulging on one side).

Professional Response: Do not attempt to pry or jack the bearing sideways. Determine if misalignment is within tolerance. If excessive, consult the engineer. The correct solution typically involves safely jacking the superstructure to relieve load, removing the bearing, and correcting the support surface profile.

o

Coordination with Other Trades: Protect bearings during adjacent activities. Shield rubber from weld spatter and sliding surfaces from paint, concrete spillage, and debris.

Handover Documentation: Create a "bearing passport" for the asset owner. Include product data, test reports, installation records, and as-built photos for each bearing location.

Facilitating Future Inspections: Design and build in safe, permanent access points for future maintenance personnel to visually inspect and measure bearing condition (e.g., shear displacement, cracking).

The journey of an elastomeric bridge bearing from specification to service is a testament to engineering precision. For the designer, it requires a deep understanding of mechanics and a meticulous specification. For the contractor, it demands respect for the product and execution with craftsmans like care. When both parties collaborate with this shared focus on quality and detail, the result is a resilient, durable bridge joint that will perform reliably for decades, securing the investment in our critical infrastructure.